How 24hr Media can Save You Time, Stress, and Money.

Wiki Article

The 24hr Media Ideas

Table of ContentsAll about 24hr Media24hr Media Can Be Fun For AnyoneSome Of 24hr MediaThe 24hr Media IdeasTop Guidelines Of 24hr Media

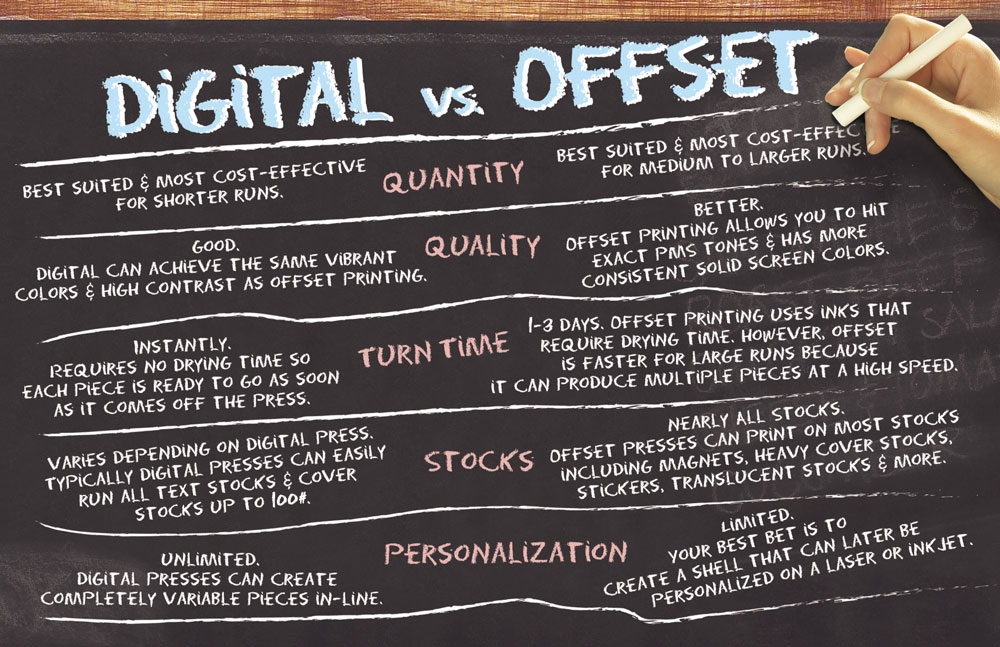

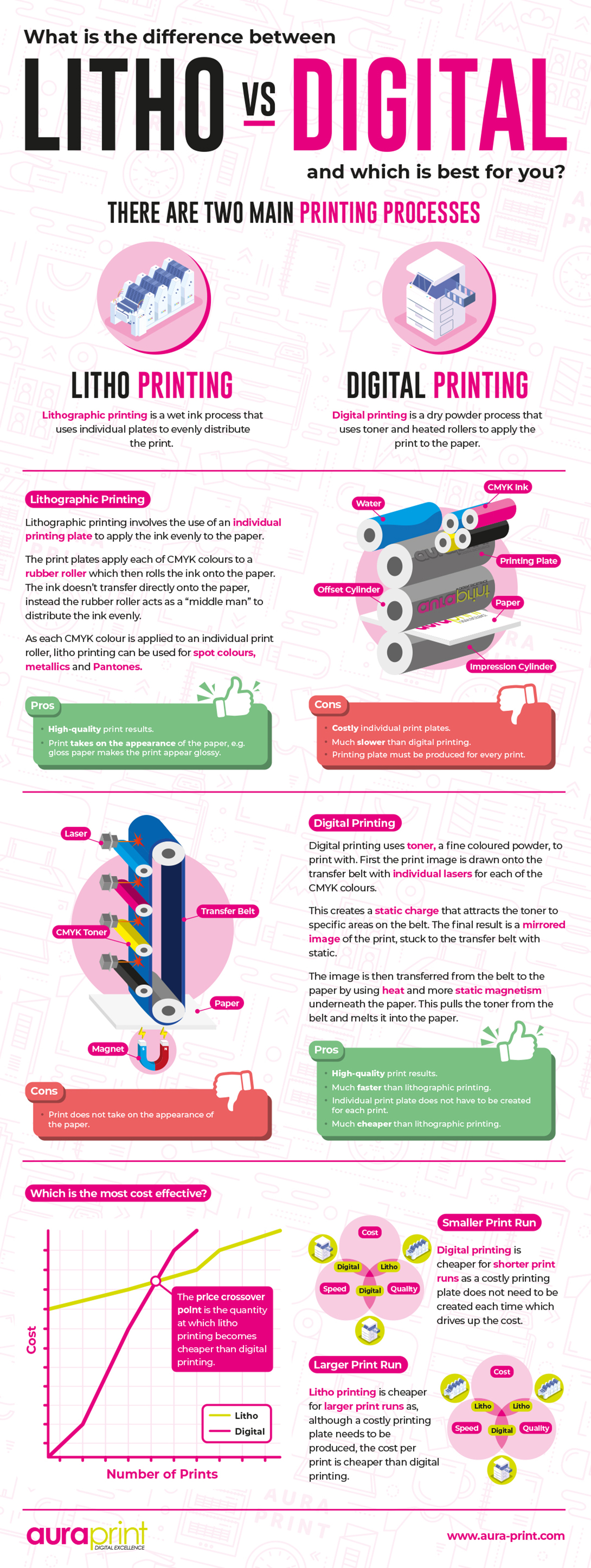

Offset, gravure printing and flexography are one of the most common kinds of conventional printing in the packaging space and each involves transferring the picture from a plate to the surface. To do this, initially the plate needs to be produced, and it is the production of these plates that require time, and cost money.According to PMMI, electronic printing permits brands and makers to react rapidly to client demands while improving the supply chain, minimizing warehousing price and waste, and delighting in faster time to market. That all audios great, however how does this modern technology do all that? The significant differentiator of these technologies is that there are no set-up costs and no plates with electronic printing.

According to Wikipedia, the biggest difference between digital printing and traditional approaches such as lithography, flexography, gravure, or letterpress is that there is no demand to replace printing plates in electronic printing, whereas in these analog printing approaches home plates are consistently replaced. This leads to quicker turnaround time and lowers price when using digital printing.

Fast manufacturing implies getting your item to market quicker. It also means it's easier and faster to make modifications later on, when you transform a dish, add a SKU, or develop seasonal product packaging. Digital printing is highly flexible, so it's very easy to make changes to the plan style rapidly. All of it goes back to the plates.

24hr Media - The Facts

Extra stock can mean even more waste down the roadway. With conventional printing techniques, short-run printing is simply not possible. Because a fantastic layout can make or damage your item, digital printing regularly produces top quality, clear and vibrant graphics each time. Digital printing on versatile pouches includes the bright, dynamic, and exact graphics that virtually beckon consumers to connect and touch them.Loading ... Are you familiar with the advantages of digital printing? Both offset and electronic printing have their area in the printing market.

In this write-up, we will certainly go over the benefits of electronic printing to aid you better understand if digital printing is just what you need. Simply placed - digital printing prints material straight onto the paper.

The 15-Second Trick For 24hr Media

As electronic printing frequently progresses, it provides more possibilities and greater output high quality everyday. In many cases, the print quality can be as high as to balance out printing. As years pass, digital print is ending up being extra available, with improved rate and high quality. This is simply the factor printing business are adding electronic printing to their deal.For offset printing, if any kind of error goes unnoticed before producing home plates, there will certainly be a high expense of producing a brand-new one. With digital printing, this is not the case (Point of sale stands). Although everyone constantly really hopes there will be no mistakes, recognizing the expense of correcting them if they take place is constantly a good idea.

This suggests each and every single item will certainly look the very same, so the opportunity you will certainly need to discard any one of them because of variances is low. Since a proofing sample is printed on the exact same device as the item itself, color proofing is very precise. Any troubles with shade will be visible on the evidence, and therefore it will certainly be possible to alter it before printing the entire run.

All about 24hr Media

Digital printing, on the various other hand, calls for marginal configuration. This is fantastic when you are in a rush to obtain your published materials.

This implies even more demands for digital on-demand print production. Every client values a personalized message. One of the advantages of electronic printing is that customizing your marketing products could not be less complicated. Cost-effective, smaller batches enable organizations to customize each order. Have a back-to-school sale? Make a flyer to target moms and dads and another one to target the pupils.

Digital printing is the excellent choice for variable information printing, like custom codes and addresses on direct-mail advertising. With electronic printing, it is less troublesome to make last-minute this link changes to your design. Often the very best form of communication is not electronic. In these instances, counting on electronic printing can make certain these orders have a minimal environmental influence.

The Basic Principles Of 24hr Media

There is likewise no requirement to clean the plates after printing. The benefits of digital printing include that there is no waste from extra or remaining ink, paper, or chemicals due to the fact that just what's required gets printed. - for extremely brief runs, electronic printing is the means to go, undoubtedly.Gone are the days of complex configurations and lengthy turn-around times - digital printing has actually changed the print market. The printing globe has actually come a long means since the days of Gutenberg's printing press. The brand-new typical is streamlined procedures and cost-effective remedies for publishing onto nearly anything you can consider.

Report this wiki page